Industrial painting and coating operations present unique ventilation challenges that impact worker safety, environmental compliance, and finished product quality. From automotive refinishing to manufacturing facilities, proper ventilation systems are essential for removing harmful volatile organic compounds (VOCs), particulates, and creating optimal application conditions. Fanmaster offers comprehensive ventilation solutions specifically designed for the demanding requirements of industrial painting environments.

The Critical Importance of Ventilation in Painting Operations

Effective ventilation in painting and coating operations addresses multiple crucial concerns beyond basic air quality. A properly designed system not only protects worker health but also improves application results and ensures regulatory compliance.

Key ventilation requirements in painting operations:

- Worker Safety Protection: Paint and coating materials contain hazardous chemicals that can cause respiratory issues, eye irritation, and long-term health problems when inhaled.

- Fire and Explosion Prevention: Many coating materials contain flammable solvents that create potentially dangerous concentrations in enclosed spaces without adequate air movement.

- Application Quality Control: Proper airflow removes overspray and maintains optimal humidity and temperature conditions for consistent coating application.

- Regulatory Compliance: Australian workplace health and safety regulations mandate specific ventilation requirements for operations involving hazardous substances.

- Environmental Protection: Appropriate filtration and extraction prevent harmful compounds from being released into the surrounding environment.

Common Ventilation Challenges in Painting Environments

Industrial painting and coating operations face several specific ventilation challenges that require specialised solutions beyond general factory ventilation systems.

Frequent ventilation issues include:

- High Contaminant Loads: Paint application generates significant particulate matter and VOC concentrations that require high-capacity extraction.

- Variable Process Requirements: Different coating materials and application methods require adjustable ventilation parameters.

- Booth Design Limitations: Existing spray booth configurations may create airflow dead spots or turbulence that affects application quality.

- Energy Consumption: Traditional high-volume ventilation systems can incur substantial operating costs.

- Filtration Effectiveness: Removing both particulates and gaseous contaminants requires multi-stage filtration approaches.

Fanmaster’s Comprehensive Ventilation Solutions

Fanmaster offers a range of ventilation products and systems designed specifically to address the unique challenges of industrial painting and coating operations.

Industrial Fume Arms: Targeted Extraction at Source

Our Industrial Fume Arms provide focused extraction directly at the point of application, capturing contaminants before they can disperse throughout the workspace.

Benefits for painting operations:

- Flexible positioning allows extraction exactly where paint application occurs

- Captures overspray and solvent vapours at source before worker exposure

- Adjustable airflow to match specific application requirements

- Easily repositioned to accommodate different workpieces or painting zones

- Flame-retardant construction for safety in environments with flammable materials

Portable Fume Extractors: Mobile Ventilation Solutions

For operations without permanent spray booths or those requiring supplemental ventilation, our Portable Fume Extractors provide high-efficiency filtration with mobility.

Advantages for coating applications:

- HEPA filtration captures 99.8% of paint particulates as small as 0.3 microns

- Activated carbon filtration removes solvent vapours and VOCs

- Mobile design allows positioning exactly where needed for specific jobs

- Provides extraction for touch-up work outside of main spray areas

- Self-contained units require no ductwork installation

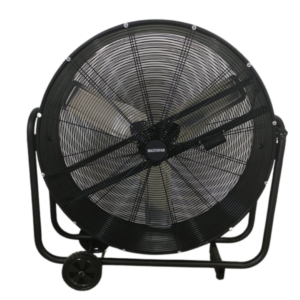

Axial Flow Fans: High-Volume Air Movement

For larger spray booths and coating areas, our Axial Flow Fans provide the high-volume air movement necessary for effective contaminant removal and proper application conditions.

Applications in painting operations:

- Creates consistent airflow patterns essential for even coating application

- Provides sufficient air changes to maintain safe working conditions

- Helps maintain optimal temperature and humidity conditions

- Available in various sizes to match specific booth dimensions

- Durable construction stands up to challenging paint environment conditions

Designing an Effective Painting Operation Ventilation System

Creating an optimal ventilation system for painting and coating operations requires careful consideration of multiple factors specific to your operation.

Key design considerations include:

- Application Methods: Different application techniques (spray, dip, brush) have varying ventilation requirements.

- Coating Materials: Water-based, solvent-based, and powder coatings each create different airborne contaminants.

- Production Volume: The frequency and duration of coating operations affect ventilation capacity needs.

- Workspace Configuration: Booth design, ceiling height, and adjacent areas all influence air movement patterns.

- Climate Considerations: Local temperature and humidity conditions affect make-up air requirements and system design.

Ventilation Best Practices for Common Painting Applications

Different painting and coating operations require specific ventilation approaches to address their unique challenges and requirements.

Spray Booth Ventilation

Spray booths represent the most common painting environment, requiring carefully engineered airflow patterns:

- Downdraft or cross-draft configurations based on application specifics

- Make-up air systems that provide properly filtered and conditioned replacement air

- Booth pressure control to prevent contaminant migration to surrounding areas

- Filter monitoring systems to ensure continued extraction effectiveness

- Regular maintenance schedules to maintain optimal performance

Open Area Painting Operations

For larger items or facilities without enclosed booths:

- Local extraction systems positioned strategically near application points

- Portable extraction units that can be positioned flexibly as work progresses

- General ventilation that supports directional airflow away from operators

- Containment strategies to limit the spread of overspray and emissions

- Zoned approaches that isolate painting activities from other operations

Specialised Coating Applications

For operations involving unique materials or methods:

- Temperature-controlled ventilation for heat-sensitive materials

- Explosion-proof systems for highly flammable coating materials

- Custom airflow configurations for complex part geometries

- Adaptable systems that can accommodate changing production requirements

- Enhanced filtration for particularly hazardous coating materials

Regulatory Compliance and Standards

Proper ventilation in painting operations is not only a matter of best practice but also a regulatory requirement. Australian standards and regulations establish specific parameters for ventilation systems in painting environments.

Key compliance considerations:

- Safe Work Australia Guidelines: Establish minimum ventilation requirements for working with hazardous substances.

- Australian Standards AS/NZS 4114: Cover spray painting booths requirements and installation.

- National Construction Code (NCC): Sets ventilation requirements for industrial buildings.

- EPA Regulations: Address emissions control from painting operations.

- Industry-Specific Standards: May apply to automotive, aerospace, or other specialised painting operations.

Why Choose Fanmaster for Your Painting Operation Ventilation Needs

Fanmaster brings specialised expertise in industrial ventilation to help ensure your painting and coating operations have the appropriate systems for safety, compliance, and quality results.

Our painting ventilation advantages:

- Industry-Specific Expertise: Our team understands the unique ventilation requirements of industrial painting operations.

- Customised Solutions: We design ventilation systems tailored to your specific application methods, materials, and facility configuration.

- Quality Products: We provide durable, high-performance ventilation equipment engineered for the demanding conditions of painting environments.

- Compliance Focus: Our solutions help ensure your operations meet relevant Australian standards and regulations.

- Ongoing Support: We offer maintenance guidance and system optimisation services to maintain ventilation performance over time.

Effective ventilation is essential for the safety, compliance, and success of your industrial painting and coating operations. Investing in proper ventilation systems protects workers, ensures regulatory compliance, and helps deliver consistent, high-quality finished products.

Ready to improve ventilation in your painting operation? Call us at 1300 900 345 for expert consultation tailored to your specific requirements. Prefer online communication? Contact us here – Contact Us