SafeWork guidelines specify that all employers must manage the risks associated with hazards in the workplace. This involves identifying hazards, and either eliminating them or controlling the risks they create.

For businesses involved in welding processes, this includes reducing the risk of harm from fumes and other airborne contaminants – such as mists, dusts, gases and vapours. The health effects of these types of contaminants can be serious, including chest tightness, asthma, lung damage, pneumonia, emphysema or even cancer.

If the welding process cannot be eliminated, then the employer must implement risk control measures – for example, through the use of fume extractors.

Fume extractors: ideal for local ventilation

The SafeWork guidelines classify equipment that captures contaminants close to its point of generation as “local exhaust ventilation”. The guidelines also state that the air from the system should not be recirculated in the work area but discharged away from workers.

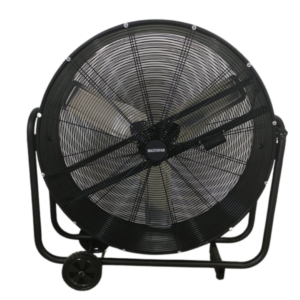

Portable fume collectors that use high-standard HEPA filters are ideal for this type of situation. HEPA stands for high-efficiency particulate air, and these types of filters capture a minimum of 99.8% of airborne contaminants down to 0.3 microns in size.

Filtering areas of these highly efficient fume collectors range from 8m2 through to 20m2, depending on need and the size of the workspace. Other features include two-directional castors and braking systems that make these systems not only portable but also very stable.

Additional risk control measures

As well as installing fume extractors, there are several other things employers can do to protect workers from welding fumes.

This includes isolating welding processes and regular job rotation to reduce length of exposure. Employers should also make sure that workers wear protective equipment and clothing where necessary – such as full-face welding helmets, steel-capped boots and welding gloves.

Lastly, workers that perform welding should always be fully trained, not only in welding processes but in all health and safety aspects of these types of tasks.

If you would like to discuss the best type of fume extractor to protect your workers from welding fumes, please don’t hesitate to get in touch with our team!