May 9, 2019

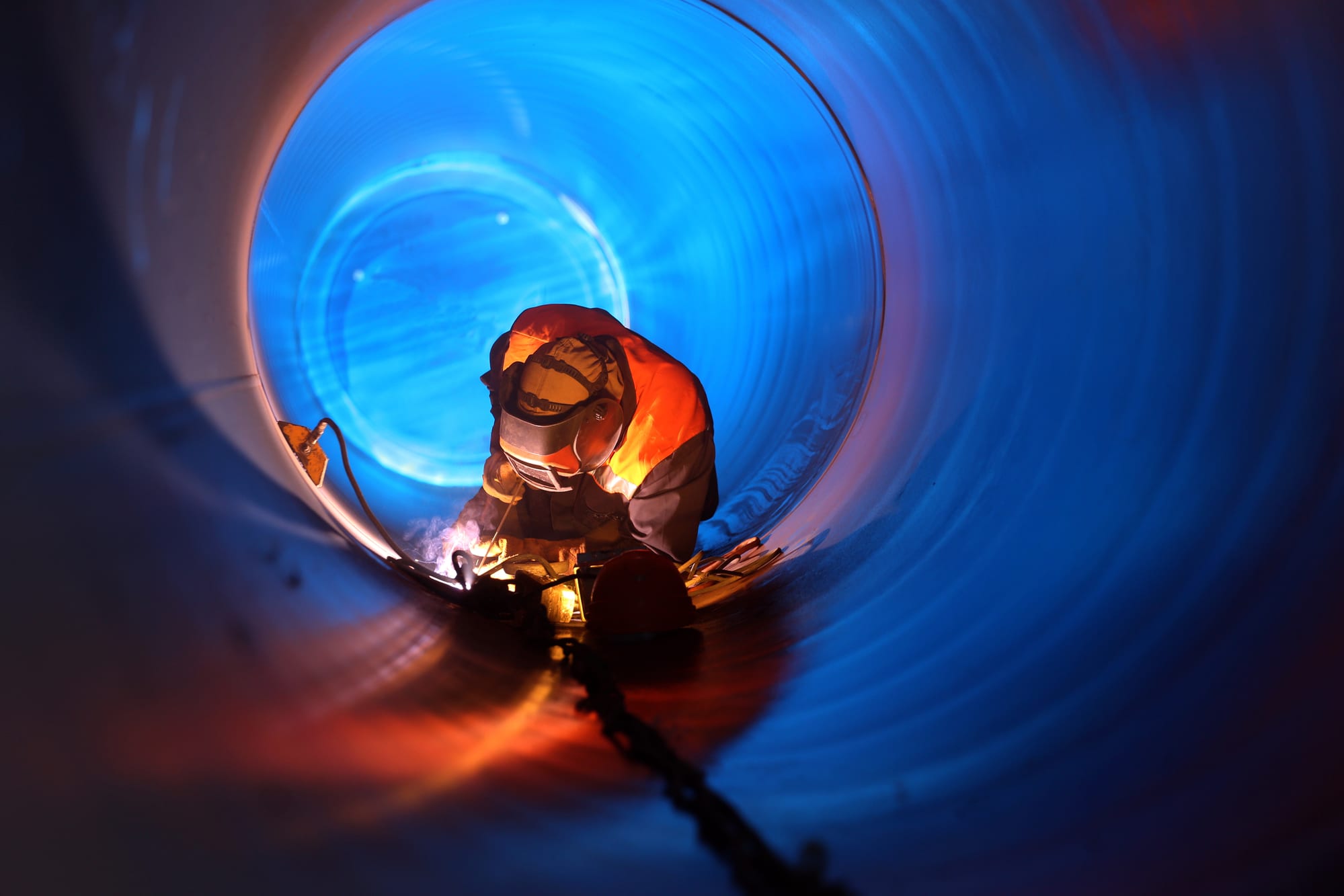

How Welding Fume Extractors Can Help Save Lives

Welding fumes – fine metal particles produced through welding that can be breathed in – have been classified as carcinogenic. This means employers in mining and other industries where welding takes place must make sure workers are protected, for example by installing welding fume extractors.

The International Agency for Research on Cancer (IARC) reclassified welding fumes from “possibly carcinogenic” to “carcinogenic” in 2017. Regular and prolonged exposures to welding fumes has been found to increase the risk of lung cancers, while exposure to UV radiation from electric arc and laser welding can increase the risk of eye and skin cancers.

What are the risk factors?

According to the Cancer Council of Australia, the degree of cancer risk from welding depends on several factors. These include the type of process, the material being welded, the consumables used, the length of time of the processes, and the workplace environment.

However, while different materials can have different impacts on health, all welding fumes are now classified as Group 1 carcinogens – which essentially means they can lead to cancer in humans.

Why welding fume extractors are crucial

Ventilation is important in all workplaces to remove contaminants and to provide high-quality clean air. However, in workplaces that use welding processes, good ventilation and air purification are especially vital.

The use of portable fume collectors can help make this happen. Welding fume extractors provide the extremely high filtration standards required for removing fumes and dust generated from welding and other processes.

Being portable systems, they can also be moved from one area of a worksite to another.

What other measures can help reduce the risks?

Employers and workers both have a role to play in reducing the risks of welding fumes.

Measures include:

- Training workers in control and safety measures, and rotation of tasks to reduce exposure levels.

- Separating welding from other activities to protect other people in the vicinity.

- PPE to protect workers from welding gas particulates. Examples include full-face welding helmets with UV-filter lenses, welding gloves, steel-toe boots and clothing to cover all exposed skin. In cases of prolonged exposure, respirators may also be needed.

- Workers can also reduce the risk to themselves by not removing protective equipment (such as helmet shields) until the fumes produced from welding have fully dissipated.

Every work situation is different, so it’s essential to get the right type and size of fume collector to protect your workers. Get in touch with us for a discussion on the best portable fume collection systems for your site and industry.